829. This hammer was made for use on the railroad.

830. Pond ice saw, as seen on the bottom left in this old catalog. According to the Dictionary of American Hand Tools:

"A saw used primarily by farmers and cattlemen for cutting holes in the ice to allow access to the water below. In cold weather the ice must be cut twice a day to allow the livestock to reach the water. Teeth of the ice saw do not have any set."

These were also used for the commercial production of ice during the 1800's.

831. Probably a heavy practice piece used in place of a

deer horn knife.

832. They look like cameras but are actually optic detectors used to control traffic signals. Instead of cutting the pavement and installing a wire for use as an inductive loop, these detectors use simple video technology to capture an image of the approach. When a vehicle enters the detection zone this image changes and the camera sends a signal to the controller that a vehicle is in a particular lane waiting for a green light.

833. Wrench for twisting wire, patented March 23, 1886, number 338,659.

834. The part of a brace that holds the drill bit.

It can be seen at the very end of this brace, to remove it just unscrew the large end piece.

Update

Four of the answers from last week have been changed or updated:

823. The small metal parts are most likely electrodes used in welding, similar to ones seen here.

826. This was marked "corn grinder", but is actually a cutter for straw, hay, and corn stalks to be used for animal feed.

Lifting the metal cover exposes the blade, which is indicated by the arrow. Turning the handle pulls in the straw and rotates the blade:

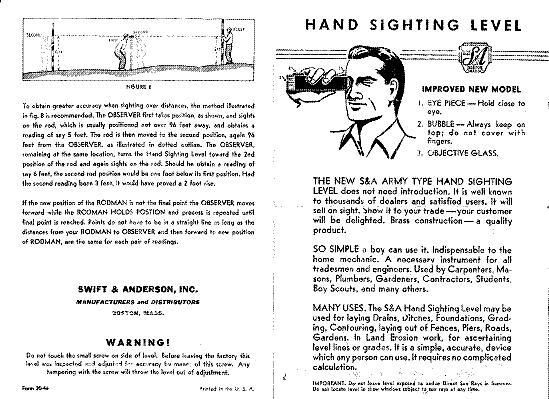

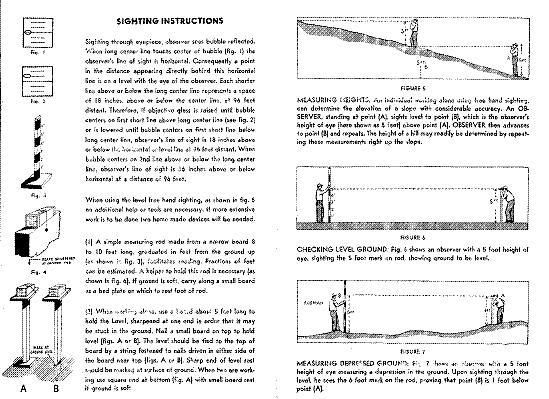

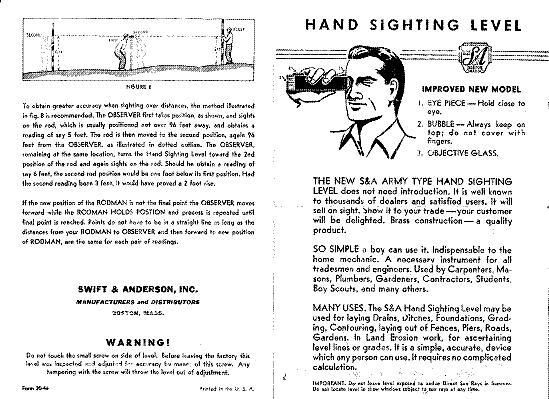

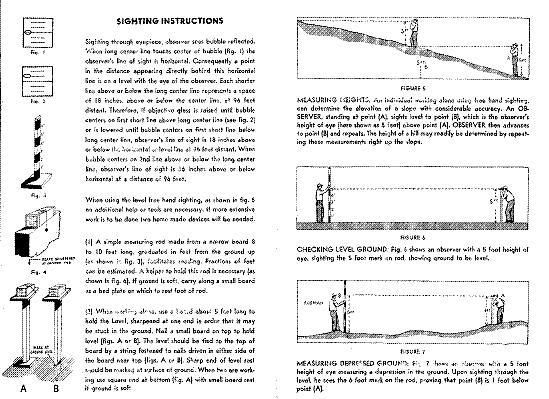

828. Hand sighting level, text on it reads: "Ward's Natural Science Establishment, Inc., Rochester N.Y.", and "Swift Instruments, Inc., Boston 25, Mass."

Thanks to Leon for sending in these instructions:

Click here to see a larger image.

Larger image

825. According to the owner, it's a Bell System conduit flaring tool, when joining two pieces of lead conduit this tool was used to widen one of the ends.

Though someone who has worked with it has a slightly different description of how it was used:

"Back in the day telephone cable came with a lead sheath or outer skin. Even as late as the late 1980's we'd get lead sheathed cable in for locations where the environment was too caustic for plastic sheathing. The last large lead sheathed cable I worked on was in Plano Texas. It was brought in between two manholes that had serious fumes from a leaking gasoline station tank.

Cable splicing back in the day was a skilled trade. Depending upon the telco you could figure five to six years to go from being an apprentice to a journeyman. The wires were connected together by stripping off the insulation off of the individual conductor and then twisting them together.

The closures over the splices were also lead. That way a lead closure could be soldered to the lead sheath for a hermetically sealed splice. The lead for the closures would come into the supply department in six foot long lengths. These lengths would come in all diameters.

Lead is soft and will deform easily. The item you're showing was used to help reshape the lead tube back into a round shape because most of the time the lead cylinder was deformed by the time it got to the job site.

Lead work was interesting and I really enjoyed it. I got into the business in the late sixties as it was being replaced by plastic sheath and mechanical closures. But occasionally a situation would come up where we had to go into an old lead closure and close it back up or the lead closure was the only thing that would work.

Skill wise the only thing I can compare it to would be blacksmithing. There was a lot of hammer work with a wood tool called a lead dresser. What we'd do is find a sleeve of lead of the proper diameter. Using the lead dresser we would hammer down the ends to where they'd fit the size of the lead sheath. If it was new cable we'd prepare the sleeve and then slide if over the cable and off to one side before starting the splicing procedure. If the splice was already done we'd form the sleeve and then split it open so it could fit over the splice. We'd close it back up and the solder it all up.

My first welding was soldering the telco lead. It wasn't easy and I believe that's what made it so much fun.

When it was done right it was beautiful, think perfect tig on aluminum without the beads. When it was not done right, well, remember your first welds?"

Last week's set is seen below, click here to view the entire post:

More discussion and comments on these photos can be found at the newsgroup rec.puzzles.

830. Pond ice saw, as seen on the bottom left in this old catalog. According to the Dictionary of American Hand Tools:

"A saw used primarily by farmers and cattlemen for cutting holes in the ice to allow access to the water below. In cold weather the ice must be cut twice a day to allow the livestock to reach the water. Teeth of the ice saw do not have any set."

These were also used for the commercial production of ice during the 1800's.

831. Probably a heavy practice piece used in place of a

deer horn knife.

832. They look like cameras but are actually optic detectors used to control traffic signals. Instead of cutting the pavement and installing a wire for use as an inductive loop, these detectors use simple video technology to capture an image of the approach. When a vehicle enters the detection zone this image changes and the camera sends a signal to the controller that a vehicle is in a particular lane waiting for a green light.

833. Wrench for twisting wire, patented March 23, 1886, number 338,659.

834. The part of a brace that holds the drill bit.

It can be seen at the very end of this brace, to remove it just unscrew the large end piece.

Update

Four of the answers from last week have been changed or updated:

823. The small metal parts are most likely electrodes used in welding, similar to ones seen here.

826. This was marked "corn grinder", but is actually a cutter for straw, hay, and corn stalks to be used for animal feed.

Lifting the metal cover exposes the blade, which is indicated by the arrow. Turning the handle pulls in the straw and rotates the blade:

828. Hand sighting level, text on it reads: "Ward's Natural Science Establishment, Inc., Rochester N.Y.", and "Swift Instruments, Inc., Boston 25, Mass."

Thanks to Leon for sending in these instructions:

Click here to see a larger image.

Larger image

825. According to the owner, it's a Bell System conduit flaring tool, when joining two pieces of lead conduit this tool was used to widen one of the ends.

Though someone who has worked with it has a slightly different description of how it was used:

"Back in the day telephone cable came with a lead sheath or outer skin. Even as late as the late 1980's we'd get lead sheathed cable in for locations where the environment was too caustic for plastic sheathing. The last large lead sheathed cable I worked on was in Plano Texas. It was brought in between two manholes that had serious fumes from a leaking gasoline station tank.

Cable splicing back in the day was a skilled trade. Depending upon the telco you could figure five to six years to go from being an apprentice to a journeyman. The wires were connected together by stripping off the insulation off of the individual conductor and then twisting them together.

The closures over the splices were also lead. That way a lead closure could be soldered to the lead sheath for a hermetically sealed splice. The lead for the closures would come into the supply department in six foot long lengths. These lengths would come in all diameters.

Lead is soft and will deform easily. The item you're showing was used to help reshape the lead tube back into a round shape because most of the time the lead cylinder was deformed by the time it got to the job site.

Lead work was interesting and I really enjoyed it. I got into the business in the late sixties as it was being replaced by plastic sheath and mechanical closures. But occasionally a situation would come up where we had to go into an old lead closure and close it back up or the lead closure was the only thing that would work.

Skill wise the only thing I can compare it to would be blacksmithing. There was a lot of hammer work with a wood tool called a lead dresser. What we'd do is find a sleeve of lead of the proper diameter. Using the lead dresser we would hammer down the ends to where they'd fit the size of the lead sheath. If it was new cable we'd prepare the sleeve and then slide if over the cable and off to one side before starting the splicing procedure. If the splice was already done we'd form the sleeve and then split it open so it could fit over the splice. We'd close it back up and the solder it all up.

My first welding was soldering the telco lead. It wasn't easy and I believe that's what made it so much fun.

When it was done right it was beautiful, think perfect tig on aluminum without the beads. When it was not done right, well, remember your first welds?"

Last week's set is seen below, click here to view the entire post:

More discussion and comments on these photos can be found at the newsgroup rec.puzzles.

0 Comments:

Post a Comment

<< Home